Home / Blog

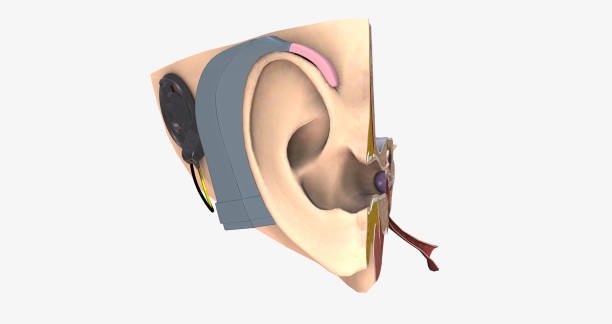

Producing high-quality injection molds for hearing aids requires careful consideration of material selection, design complexity, tooling and equipment, regulatory compliance, and quality control. Overcoming technical barriers such as miniaturization, tight

Unlocking Success: A Comprehensive Guide to Injection Mold Manufacturing. Discover the intricacies of this specialized industry and how we excel in delivering high-quality molds. From design to fabrication, we leverage

CSX MOLD’s custom injection molds offer a revolutionary solution for hearing aid manufacturers. With a focus on precision, customization, efficiency, and durability, CSX MOLD addresses the challenges faced by manufacturers

The control parameters for injection molding include plasticizing temperature, melting temperature, injection pressure, injection speed, holding time, holding switch point, and mold temperature. These parameters must be adjusted based on

Maintaining a positive relationship with customers is essential for injection molding mold factories. Effective communication, understanding customer needs, delivering quality products, providing excellent customer service, and building long-term relationships are

Injection molding is a manufacturing process that relies on high-quality molds made of steel or aluminum to create complex parts with high levels of accuracy and repeatability. The molds are

©Copyright 2023. All Rights Reserved. Rometheme

Want to know your mold-making costs? Leave your details and I’ll get back to you.